Silicon Tetrachloride Distillation Process

2012 due to the impact of the European debt crisis and the "double counteraction" investigation in Europe and the United States. In 2013, with the gradual recovery of the polysilicon industry, the silicon tetrachloride industry gradually entered a relatively stable development stage. The country's silicon tetrachloride industry produced about 140,000 tons in 2014 and will double that by 2021. The country's silicon tetrachloride industry is expected to produce more in 2022.

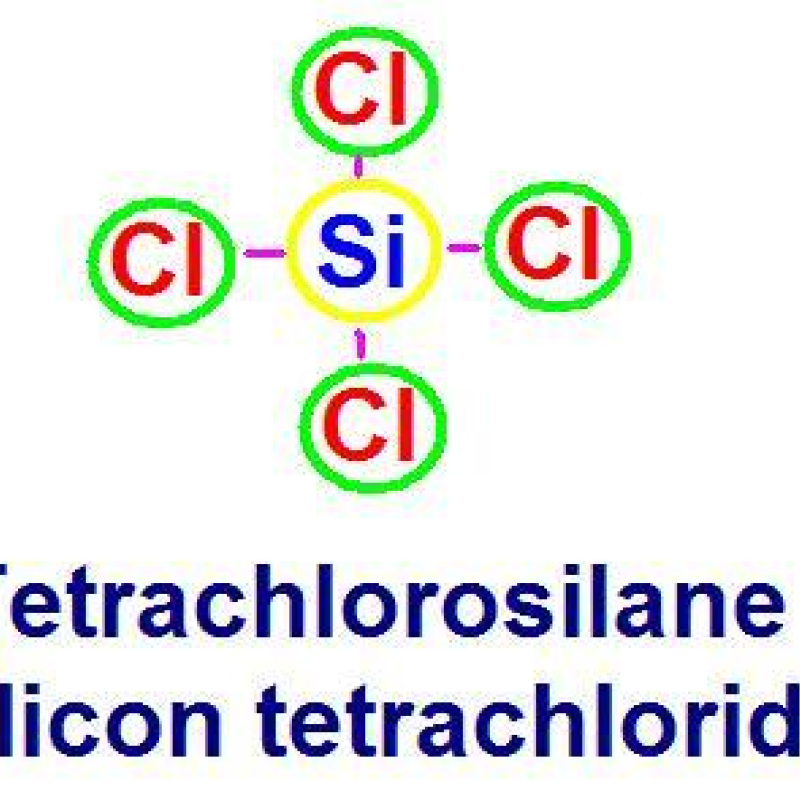

Distillation is the use of SiCl4, and the difference between the relative volatility of impurities components, through several partial gasification and partial condensation process, to achieve the separation of mixed liquid, so as to obtain high purity silicon tetrachloride products. The method has the advantages of simple operation, high degree of automation, continuous formation and large yield, but it is difficult to remove the impurities with the relative volatility of SiCl4 and BCl3, AlCl3, FeCl3, PCl3 and other polar impurities. The commonly used distillation tower has sieve plate tower and packed tower, and the tower equipment made of high purity stainless steel or quartz glass is preferred to avoid the contamination of silicon tetrachloride in purification and improve the purification effect.

Mr. He proposed a continuous distillation method of high purity silicon tetrachloride for optical fiber. The method through the coarse SiCl4, first into the decontamination component tower for decontamination, and then the obtained tower tank tank out of the material into the decontamination tower for decontamination, and finally in the side line to get high purity grade SiCl4 for optical fiber. The method can recycle SiCl4 in polysilicon production and realize continuous and stable production, so it is suitable for large-scale industrial production.