Trichlorosilane Reduction Process

Trichlorosilane reduction process control method This method includes preliminary reaction control stage, stable reaction control stage and final reaction control stage. In the preliminary reaction control stage, the flow of SiHCl3 is controlled below 260 cubic meters/hour, the flow of H2 is controlled below 520 cubic meters/hour, and the current is controlled between 30-1000 amps. In the stable reaction control stage, the flow of SiHCl3 is controlled between 175-260 cubic meters/hour, the flow of H2 is controlled between 385-520 cubic meters/hour, and the current is controlled between 1000-2000 amps. In the final reaction control stage, the flow of SiHCl3 is controlled between 130-250 cubic meters/hour. The flow of H2 is controlled between 360 and 520 m3 / h, and the current is controlled between 100 and 800 amp. The invention improves the yield of trichlorosilane and reduces the energy consumption, reducing the production cost of enterprises.

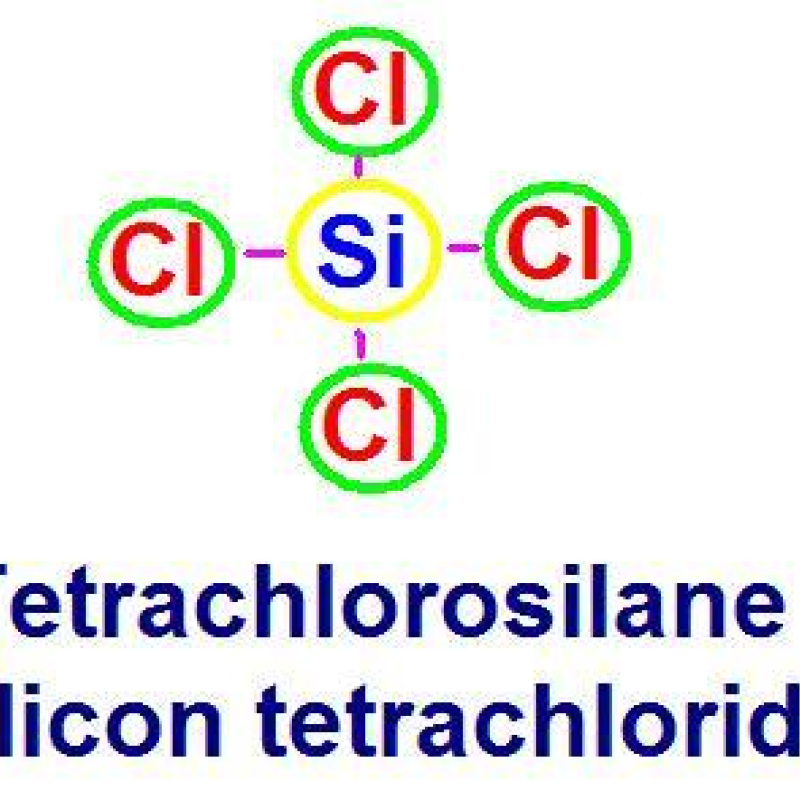

The principle is to reduce high purity trichlorosilane with high purity hydrogen on the high purity silicon core at about 1100℃ to generate polycrystalline silicon deposited on the silicon core. On the basis of the traditional Siemens process, the improved Siemens process is equipped with a supporting process of energy saving, consumption reduction, recycling and utilization of a large amount of H2, HCI, SiCI4 and other by-products and a large amount of by-production heat energy. In polysilicon into production process, using H2 reducing chemical hydrogen silicon in silicon rod generated on the steps of polysilicon is the most important step, the process of polysilicon production rate of high and low key also lies in the control of the process steps, thus to improve the polysilicon production rate is the key point of control of the process steps, and the process step is under the condition of high temperature reaction process, high energy consumption, To reduce energy consumption, it is also necessary to control the process step reasonably.