Introduction To Trichlorosilane Industry Growth

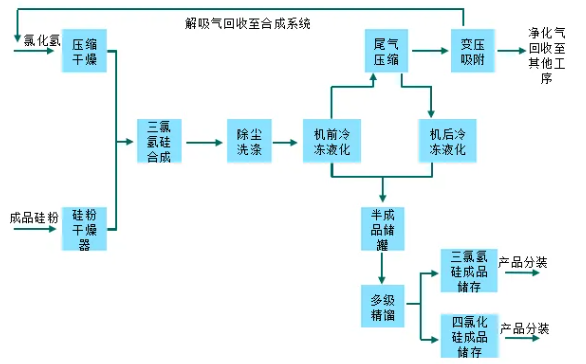

Currently, polysilicon in the head of the enterprise can be self-sufficient in secondary packaging, without the need for external harvesting. But in the first phase of the operation, it does need to be harvested. For example, a 100,000-ton project would require 20,000 tons of PV grade trichlorosilane to fill early towers and tanks. In addition, enterprises will basically plan the quantity of trichlorosilane in advance, lock part of the price of trichlorosilane, and the rest of the price is signed separately. According to the survey, for every 1-ton increase in polysilicon production capacity, polysilicon manufacturers need to invest about 0.2 tons of trichlorosilane at a time to replenish liquid level and clean the system; In the production stage, for every 1 ton of polysilicon produced by the polysilicon manufacturer, 0.3-0.5 tons of trichlorosilane is consumed to supplement the loss of the circulation system.

Silane coupling agent product price growth is very obvious, compared with the same period last year growth of 118%. Upstream raw material trichlorosilane price rise, silane products for the high price operation provides a strong support.

Reporters learned that trichlorosilane is mainly used in the production of polysilicon, silane coupling agent, silane coupling agent is the second largest downstream market of trichlorosilane, in recent years the demand is more exuberant. According to the process characteristics, in the initial stage of the polycrystalline silicon project, more trichlorosilane needs to be added in the starting link because the back-end device is started first and the cold hydrogenation process starts later. In the subsequent production and operation link, a small amount of trichlorosilane needs to be added after the whole production device runs through.