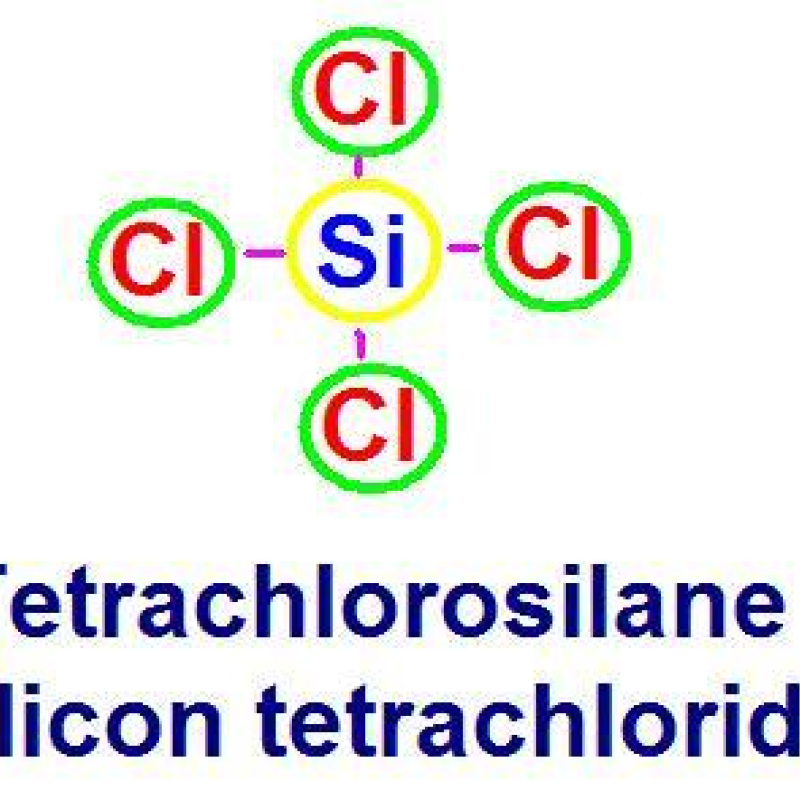

Silicon tetrachloride

Domestic enterprises mainly produce medium and low-end silicon tetrachloride products, and the market share of high-purity optical fiber grade silicon tetrachloride is relatively low. The product import dependence is relatively high, and the domestic replacement space of high-purity optical fiber grade silicon tetrachloride is broad. In recent years, the high purity optical fiber silicon tetrachloride industry develops slowly in our country. There are few high purity optical fiber silicon tetrachloride enterprises that can supply stably in our country. However, in terms of good factors, with the progress of science and technology, China's silicon tetrachloride purification technology has been breakthrough, metal ion impurities, hydrogen containing impurities removal and other aspects have been better, high purity optical fiber silicon tetrachloride production capacity is gradually improved.

In silicon tetrachloride purification, boron is the most difficult impurity to remove. Researchers have proposed compound method to remove boron from silicon tetrachloride, which has achieved satisfactory results and has been widely used in industrial production. The key to the application of complex method lies in the selection of complexing agent, which requires the complexing agent to react with boron chloride, which can form a more stable complex, and the complexing agent can not react with silicon tetrachloride and chloride.

Based on the above requirements, researchers carried out a large number of experiments, and finally found that sodium pyrrole dithiocarbamate tetrahydrohydride is an efficient complexing agent.