Silicon Tetrachloride Hydrogenation Into Trichlorosilane

The development of photovoltaic industry has greatly promoted the development of polysilicon industry, and the production of polysilicon produces a large number of silicon tetrachloride by-products. In order to the sustainable development of polysilicon industry, comprehensive utilization of silicon tetrachloride problems must be resolved, silicon and silicon tetrachloride hydrogenation preparation into chemical hydrogen is the most effective way to deal with silicon tetrachloride, this method can not only get rid of silicon tetrachloride, at the same time generate polysilicon production of silicon raw materials chemical hydrogen, greatly reduce the production cost.

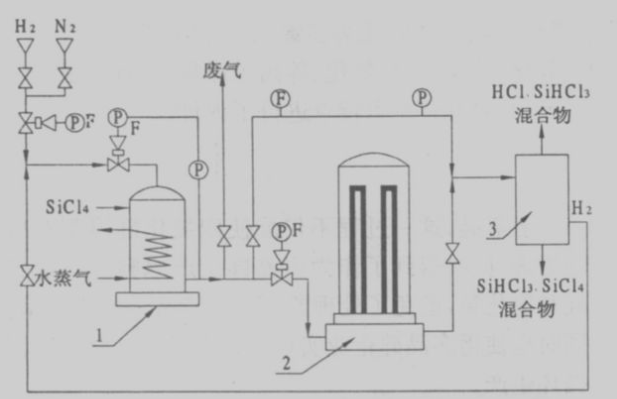

High temperature hydrogenation of silicon tetrachloride is an important method to treat silicon tetrachloride as a by-product of polysilicon. High temperature hydrogenation is silicon tetrachloride and hydrogen as raw materials, heated by 1200 ~ 1250℃ graphite heater, thermal reduction reaction to produce trichlorosilane.

The advantages of the process are that the whole system is closed circulation, suitable for continuous and stable operation; Trichlorosilane products of high purity, need to distillation links less. The disadvantage is that the reaction needs to be carried out at 900~1400℃ or even higher temperature and high pressure of 1~35MPa, and the energy consumption is great; As the heating device of the reactor is isostatic graphite belt, it is easy to form methane and other gases under high temperature and pressure conditions, which will bring carbon pollution to the polysilicon in the closed-circuit cycle production.