Trichlorosilane is mainly used in the manufacture of polysilicon and silane coupling agents, among which polysilicon is the most important downstream application area of trichlorosilane, accounting for 32% of the consumption in 2021, and silane coupling agent consumption accounted for 25%. The market is still in good condition.

Contact Now

Trichlorosilane is a higher degree of marketization, competition is more adequate industry. The price of industrial products is easily affected by upstream raw materials and downstream demand. Trichlorosilane production raw materials are mainly industrial silica powder and liquid chlorine, if the raw material prices rise sharply, it profits will be under pressure. The price fluctuation of trichlorosilane has little effect on the profits of polysilicon enterprises. Even if the price is temporarily low, polysilicon prices still have upward momentum.

Contact Now

Silane coupling agent product price growth is very obvious, compared with the same period last year growth of 118%. Upstream raw material trichlorosilane price rise, silane products for the high price operation provides a strong support. Reporters learned that trichlorosilane is mainly used in the production of polysilicon, silane coupling agent, silane coupling agent is the second largest downstream market of trichlorosilane, in recent years the demand is more exuberant.

Contact Now

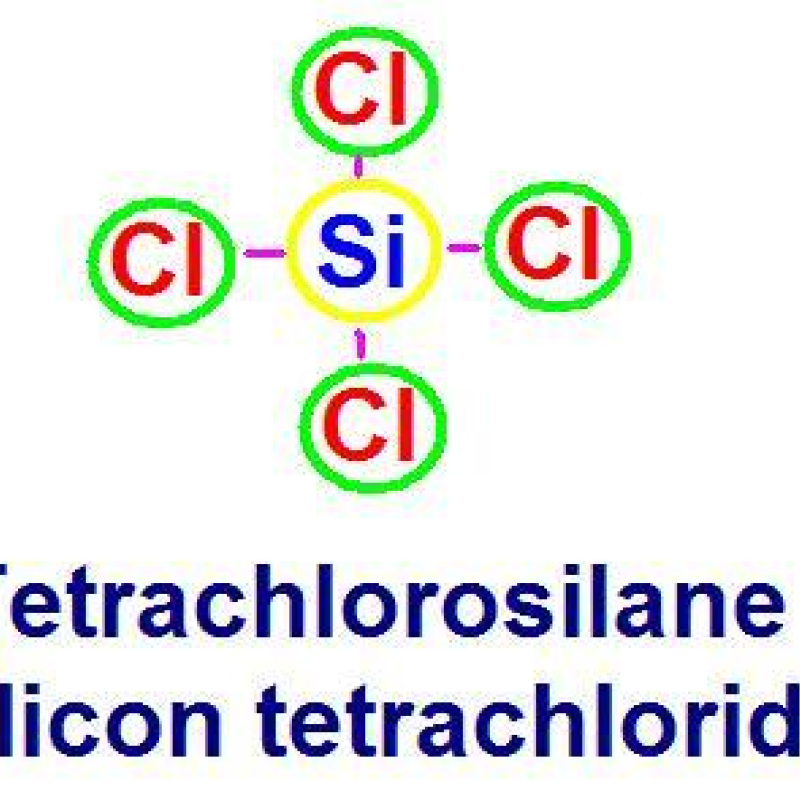

SiCl4 is one of the most important inorganic silicon compounds, is a colorless, transparent, flowing smoke liquid, with suffocating odor, soluble in benzene, ether, chloroform and other most organic solvents. Silicon tetrachloride is a volatile liquid with strong asphyxiating odor. It can be used as raw materials for the production of gaseous silica, high purity silicon and organosilicide. The upstream of the silicon tetrachloride industry chain is the raw material market, mainly silicon powder, ferrosilicon, hydrogen chloride, etc.

Contact Now

Since May 2022, trichlorosilane has been sustained upward by the downward trend in silicon metal prices.

Contact Now

In recent years, China's polysilicon production has shown geometric development, but the disposal of polysilicon by-product silicon tetrachloride has become a difficult to step over the development of polysilicon industry "sill", let the silicon industry wear the hat of high pollution.

Contact Now

The purity of hydrogen is high, and the purity of cyclohexylamine reaches over 99.95%, which is higher than the industry standard by 99.8%. The purity of dicyclohexylamine is higher than 99.5%, which is 99% higher than the standard of peer enterprises. Recycling the industrial chain can reduce the comprehensive cost of the factory. There are three aniline factories in Dongying, Shandong, Huai 'an, Jiangsu and Tianji, Shanxi within 400 kilometers. The technology is mature, and the workers have about twenty years of practical experience.

Contact Now

A high purity trichlorosilane differential pressure coupled distillation process, using the high pressure tower top steam as the heat source of the low pressure tower reboiler, realized the energy integration and process optimization. Chemical simulation software PRO/Ⅱ8.1 was used to simulate the design parameters of two columns of high purity trichlorosilane differential pressure coupled distillation process and three columns of high purity trichlorosilane differential pressure coupled distillation process.

Contact Now

The invention relates to a tail gas refining method, especially a method for hydrogenation of aniline to produce dicyclohexylamine tail gas deamination and hydrogen refining, which belongs to the technical field of chemical industry.

Contact Now

With the rapid growth of downstream PV demand, photovoltaic grade trichlorosilane continues to be in short supply. The application of PV grade trichlorosilane in the production of polysilicon includes a one-time requirement for the first commissioning, which accounts for about 20% of the total capacity. Second, the requirement for chlorine supplementation during continuous production accounts for about 10 to 30 percent of total production. On the supply side, the expansion of trichlorosilane production has been conservative in the past.

Contact Now

Electronic grade trichlorosilane sihc13 is colorless, flammable, corrosive liquid and has a suffocating odor. Hydrolyze rapidly in wet air to produce hydrogen chloride: boiling point 31.9 ':. Melting point 126.5 c:. Liquid density 134ukgi resistance: in the air "}", the flammability limit is B.9% - 7U}'u. Flash point - 28. U}.

Contact Now

The mixture of trichlorosilane and polysilicon, which is a by-product of the recombination from the bottom of the distillation column in the production of trichlorosilane and polysilicon, was used as raw material to prepare silica by gas phase hydrolysis. The effects of gasification temperature, flow rate and flow ratio of water vapor and chlorosilane mixture on physicochemical properties of the products were investigated.

Contact Now

It is obtained by catalytic hydrogenation of aniline and can be divided into atmospheric pressure method and pressure method. In addition, cyclohexamine can be prepared by catalytic ammonolysis of cyclohexane or cyclohexanol, reduction of nitrocyclohexane, and catalytic ammonolysis of cyclohexanone in the presence of hydrogen.The refining process often contains impurities such as aniline and water.

Contact Now

The purity of dicyclohexylamine is better than 99.five%, that is 99% higher than the standard of peer organizations. recycling the economic chain can lessen the comprehensive value of the manufacturing facility. there are 3 aniline factories in dongying, shandong, huai 'an, jiangsu and tianji, shanxi within four hundred kilometers. the generation is mature, and the people have about twenty years of practical enjoy.

Contact Now

Cyclohexylamine (CHA) is a primary amine, can be miscible with water with infinite ratio, the molecule is small, easy to adsorb on the metal surface, its shielding effect is better than long chain primary amine and secondary amine, so it can effectively prevent the invasion of corrosive ions, thereby improving corrosion resistance, especially the ability to inhibit corrosion.The corrosion inhibition of 304 stainless steel by cyclohexylamine in sodium chloride medium was studied in detail.

Contact Now

Cyclohexylamine has the chemical properties of a primary amine. Carbonates that are strongly alkaline and absorb carbon dioxide in the air to form white crystals. It can react with acyl chloride, anhydride and ester to form N-acyl. React with nitrite to give alcohol. Hydroxymethyl compounds are formed by reaction with formaldehyde in alkaline solution. Reacts with carbon disulfide to form dithiocarbamate. Reacts with aldehydes to form Schiff bases.This product is used to prepare cyclohexanol, caprolactam, acetate fiber and nylon 6, etc.

Contact Now

The purity of dicyclohexylamine is higher than ninety nine.5%, that is 99% better than the same old of peer groups. recycling the economic chain can lessen the comprehensive price of the producing facility. there are three aniline factories in dongying, shandong, huai 'an, jiangsu and tianji, shanxi within four hundred kilometers. the era is mature, and the people have about 20 years of practical enjoy.

Contact Now

Trichlorosilane (TCS or SiHCl3) is generated as follows within a high temperature, pressurized reactor: Si + 3 HCl ➡ SiHCl3 + H2 ,Si + 3 SiCl4 +2 H2 ➡ 4 SiHCl3 .The TCS is then sent to the CVD (Chemical Vapor Desposition) reactor. In the Siemens process, high-purity silicon "starter" rods or hairpins are exposed to trichlorosilane at 1150 °C in the CVD reactor.

Contact Now

The purity of dicyclohexylamine is better than ninety nine.5%, this is 99% higher than the identical old of peer companies. recycling the economic chain can reduce the complete fee of the manufacturing facility. there are 3 aniline factories in dongying, shandong, huai 'an, jiangsu and tianji, shanxi within 4 hundred kilometers. the technology is mature, and the human beings have approximately twenty years of realistic experience.

Contact Now

High temperature hydrogenation of silicon tetrachloride is an important method to treat silicon tetrachloride as a by-product of polysilicon. High temperature hydrogenation is silicon tetrachloride and hydrogen as raw materials, heated by 1200 ~ 1250℃ graphite heater, thermal reduction reaction to produce trichlorosilane. The advantages of the process are that the whole system is closed circulation, suitable for continuous and stable operation; Trichlorosilane products of high purity, need to distillation links less.

Contact Now

At present, there are two main synthesis methods of trichlorosilane: one is the traditional synthesis method, that is the silicon chloride method. The other is hydrolyzation of tetrachloride. At present, the mainstream method of polysilicon production is the modified Siemens method, using trichlorosilane reduction method. In recent years, with the continuous decline of polysilicon price, polysilicon production enterprises pay more and more attention to the control of production cost.

Contact Now

Silicon tetrachloride is mainly used in the manufacture of silicone esters, gaseous silica, silicone monomer, silicone oil, high temperature insulating paint, silicone resin, silicone rubber and so on. High-purity silicon tetrachloride is the main raw material for manufacturing fiber prefabricated rod, and the quality of fiber prefabricated rod directly determines the fiber performance. Therefore, high-purity silicon tetrachloride is the core raw material of fiber industry.

Contact Now

The production process of trichlorosilane is mostly prepared by reaction of gold-grade silicon metal powder and hydrogen chloride gas in a fluidized bed reactor. Generally using gold grade metal silicon powder, hydrogen chloride gas by the combustion reaction of chlorine and hydrogen gas. Reaction temperature is 300-400 degrees, most of the pressure using micro positive pressure operation.

Contact Now

The principle is to reduce high purity trichlorosilane with high purity hydrogen on the high purity silicon core at about 1100℃ to generate polycrystalline silicon deposited on the silicon core. On the basis of the traditional Siemens process, the improved Siemens process is equipped with a supporting process of energy saving, consumption reduction, recycling and utilization of a large amount of H2, HCI, SiCI4 and other by-products and a large amount of by-production heat energy.

Contact Now