Nitrocyclohexane reduction method: This method takes nitrocyclohexane and hydrogen as raw materials, using reducing agent to generate cyclohexylamine, because nitrocyclohexane raw materials are difficult to obtain, this method is basically eliminated. Moreover, the process has some defects, such as low one-way conversion of aniline and poor selectivity of dicyclohexylamine.

Contact Now

Cyclohexanol gas-phase ammoniation method: it is the liquid hydrogenation of cyclohexanol and ammonia to cyclohexanamine and dicyclohexanamine under the action of nickel/silica catalyst. The yield of cyclohexanol and dicyclohexanamine is 3:1, and the conversion rate of cyclohexanol is about 70%, which has not been reported in industrialization in China.

Contact Now

A method of cyclohexylamine catalytic production of biodiesel with prickly ash seed oil as raw material is described as follows: prickly ash seed oil is mixed with methanol and the catalyst cyclohexylamine.

Contact Now

To explore the application value of ion chromatography in the detection of cyclohexylamine in workplace air. Workplaces containing cyclohexylamine in the production of raw materials were selected as sampling sites, and the content of cyclohexylamine in workplaces was detected by ion chromatography. At the same time, the precision and recovery rate of ion chromatography, desorption efficiency, sampling efficiency and other cation interference characteristics were analyzed.

Contact Now

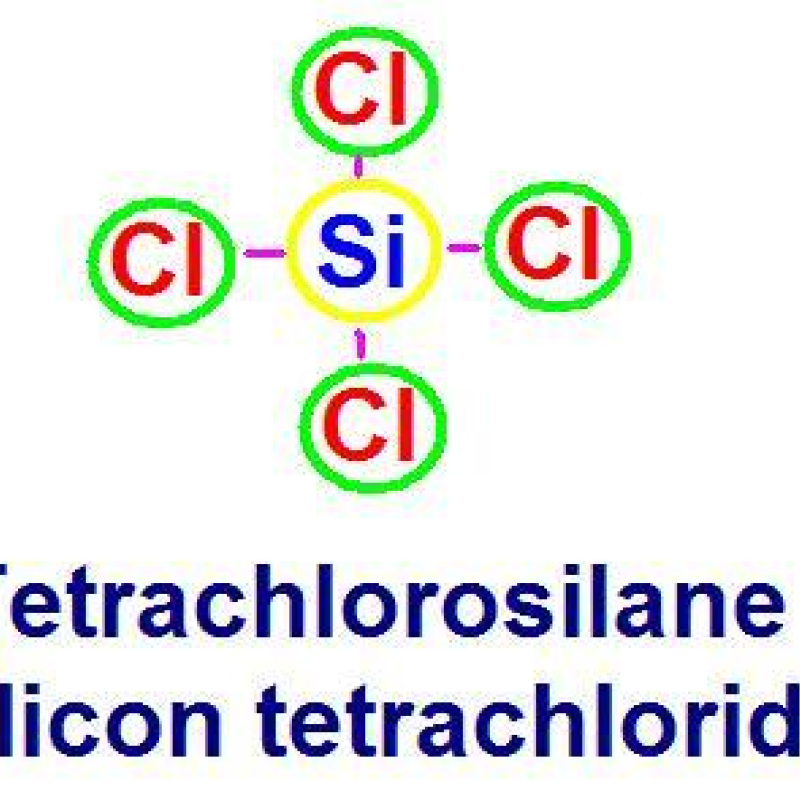

Silicon tetrachloride is an important raw material and intermediate product in the process of organic silicon synthesis and polysilicon production. Under different environmental conditions, silicon tetrachloride can react with a variety of substances to produce new substances.

Contact Now

At present, there are two main synthesis methods of trichlorosilane: one is the traditional synthesis method, that is the silicon chloride method. The other is hydrolyzation of tetrachloride. At present, the mainstream method of polysilicon production is the modified Siemens method, using trichlorosilane reduction method. In recent years, with the continuous decline of polysilicon price, polysilicon production enterprises pay more and more attention to the control of production cost.

Contact Now

The mixture of trichlorosilane and polysilicon, which is a by-product of the recombination from the bottom of the distillation column in the production of trichlorosilane and polysilicon, was used as raw material to prepare silica by gas phase hydrolysis. The effects of gasification temperature, flow rate and flow ratio of water vapor and chlorosilane mixture on physicochemical properties of the products were investigated.

Contact Now

The production process of trichlorosilane is mostly prepared by reaction of gold-grade silicon metal powder and hydrogen chloride gas in a fluidized bed reactor. Generally using gold grade metal silicon powder, hydrogen chloride gas by the combustion reaction of chlorine and hydrogen gas. Reaction temperature is 300-400 degrees, most of the pressure using micro positive pressure operation.

Contact Now

Foreign production and application are mainly concentrated in the western developed countries and regions, the main manufacturers are the United States Air Products company, Celanes company, Germany BASF, Bayer company and other scale manufacturers. But in Europe, cyclohexylamine has been in short supply due to the limitation of hydrogen feedstock. With the rapid development of the food additive cyclamate and rubber industry, the consumption of cyclohexylamine has been increasing at an average annual rate of more than 10%.

Contact Now

In recent years, China's polysilicon production has shown geometric development, but the disposal of polysilicon by-product silicon tetrachloride has become a difficult to step over the development of polysilicon industry "sill", let the silicon industry wear the hat of high pollution.

Contact Now

With the rapid growth of downstream PV demand, photovoltaic grade trichlorosilane continues to be in short supply. The application of PV grade trichlorosilane in the production of polysilicon includes a one-time requirement for the first commissioning, which accounts for about 20% of the total capacity. Second, the requirement for chlorine supplementation during continuous production accounts for about 10 to 30 percent of total production. On the supply side, the expansion of trichlorosilane production has been conservative in the past.

Contact Now

In silicon tetrachloride purification, boron is the most difficult impurity to remove. Researchers have proposed compound method to remove boron from silicon tetrachloride, which has achieved satisfactory results and has been widely used in industrial production.

Contact Now

SiCl4 is one of the most important inorganic silicon compounds, is a colorless, transparent, flowing smoke liquid, with suffocating odor, soluble in benzene, ether, chloroform and other most organic solvents. Silicon tetrachloride is a volatile liquid with strong asphyxiating odor. It can be used as raw materials for the production of gaseous silica, high purity silicon and organosilicide. The upstream of the silicon tetrachloride industry chain is the raw material market, mainly silicon powder, ferrosilicon, hydrogen chloride, etc.

Contact Now

Cyclohexylamine has the chemical properties of a primary amine. Carbonates that are strongly alkaline and absorb carbon dioxide in the air to form white crystals. It can react with acyl chloride, anhydride and ester to form N-acyl. React with nitrite to give alcohol. Hydroxymethyl compounds are formed by reaction with formaldehyde in alkaline solution. Reacts with carbon disulfide to form dithiocarbamate. Reacts with aldehydes to form Schiff bases.This product is used to prepare cyclohexanol, caprolactam, acetate fiber and nylon 6, etc.

Contact Now

Silane coupling agent product price growth is very obvious, compared with the same period last year growth of 118%. Upstream raw material trichlorosilane price rise, silane products for the high price operation provides a strong support. Reporters learned that trichlorosilane is mainly used in the production of polysilicon, silane coupling agent, silane coupling agent is the second largest downstream market of trichlorosilane, in recent years the demand is more exuberant.

Contact Now

The invention relates to a synthesis method of dicyclohexylamine, which comprises the following steps: in a hydrogenation reactor, aniline and hydrogen are hydrogenated in gas phase under the catalyst to obtain DCHA crude product.The replacement reaction was carried out with aniline and DCHA crude product to obtain the replacement mother liquor. The replacement mother liquor was delight and refined, and DCHA product was obtained at the top of the refining tower.

Contact Now

A vapor phase corrosion inhibitor preparation method, including the following steps :a. Dispersing montmorillonite in deionized water, beating, stirring, and then taking the suspension of the solution to add morpholine, heating the solution to evaporate and precipitate crystals.b. Add formaldehyde to the solution in Step a and let it stand; add dicyclohexylamine and let it stand; then add the mixed solution of benzoic acid and acetone to the solution and let it stand to generate white slurry.

Contact Now

Trichlorosilane is a higher degree of marketization, competition is more adequate industry. The price of industrial products is easily affected by upstream raw materials and downstream demand. Trichlorosilane production raw materials are mainly industrial silica powder and liquid chlorine, if the raw material prices rise sharply, it profits will be under pressure. The price fluctuation of trichlorosilane has little effect on the profits of polysilicon enterprises. Even if the price is temporarily low, polysilicon prices still have upward momentum.

Contact Now

At present, there are few reports on the quantitative analysis of dicyclohexylamine and impurities, so it is necessary to study them separately accurate quantitative analysis method. Since dicyclohexylamine has no ultraviolet absorption, the quantitative analysis method of dicyclohexylamine by high performance liquid chromatography evaporative light scattering detector was studied.

Contact Now

At present, amine salt type corrosion inhibitors are widely used and have superior effects. Through physical and chemical analysis of the sample, ultraviolet spectrum, infrared spectrum, nuclear magnetic resonance spectroscopy and ion chromatography and other series of analysis and prediction to determine the role of different ions of dicyclohexylamine salt corrosion inhibitor in steel corrosion analysis, and finally determined that the solid sample may be dicyclohexylamine nitrite.

Contact Now

By controlling the parameters in each step, such as time, temperature, pressure, etc.The yield of cyclohexylamine products is high, the product yield is more than 99%, the quality is stable, the yield is high, the production capacity is large, the side reaction is less, and a small amount of by-product dicyclohexylamine in the reaction can be recovered and purified, and the added value of the products can be increased.

Contact Now

The method of species co-production of cyclohexylamine and dicyclohexylamine and the catalyst system used for the method. The method includes the following steps :(1) the raw material aniline, cyclohexanone, ammonia, hydrogen after the loading load RhNi catalyst first section reactor, the first reaction liquid.(2) The reaction solution containing cyclohexylamine and dicyclohexylamine was obtained through the second stage reactor loaded with RhCo catalyst.

Contact Now

The principle is to reduce high purity trichlorosilane with high purity hydrogen on the high purity silicon core at about 1100℃ to generate polycrystalline silicon deposited on the silicon core. On the basis of the traditional Siemens process, the improved Siemens process is equipped with a supporting process of energy saving, consumption reduction, recycling and utilization of a large amount of H2, HCI, SiCI4 and other by-products and a large amount of by-production heat energy.

Contact Now

DCHA at home and abroad is usually a by-product of CHA production. In the process of CHA synthesis by aniline hydrogenation, about 10% of DCHA can be obtained by by-product. In addition, according to the different catalysts, the yield of DCHA prepared by aniline hydrogenation can reach up to 70%, and the yield of cyclohexylamine (CHA) is 30%.Benzene, cyclohexane, cyclohexanol, N-cyclohexylcyclohexamine, phenylcyclohexylamine and other by-products will be generated in the reaction.

Contact Now