In silicon tetrachloride purification, boron is the most difficult impurity to remove. Researchers have proposed compound method to remove boron from silicon tetrachloride, which has achieved satisfactory results and has been widely used in industrial production.

Contact Now

In recent years, China's polysilicon production has shown geometric development, but the disposal of polysilicon by-product silicon tetrachloride has become a difficult to step over the development of polysilicon industry "sill", let the silicon industry wear the hat of high pollution.

Contact Now

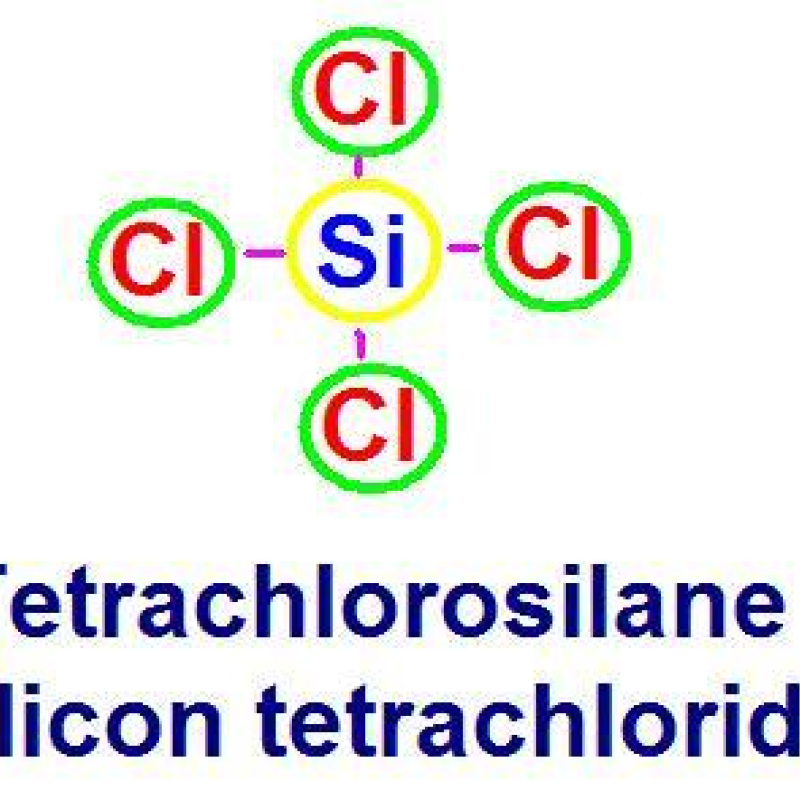

The basic principle of solid adsorption is adsorption separation based on the different polarity of chemical bonds of each component in a compound. Silicon tetrachloride is a symmetric molecule with no dipole moment. In contrast, the contained impurities such as BCl3, AlCl3, FeCl3, PCl3, etc. are asymmetric molecules with considerable dipole moments, which strongly tend to form additive chemical bonds and are easily adsorbed by the adsorbent.

Contact Now

Silicon tetrachloride is an important chemical raw material, it is widely used to produce high-purity silicon, silane, silicone ester, silicone oil, silica gel and other products, widely used in ink, paint, resin, rubber, medicine, grease and other fields; Silicon tetrachloride can also be used to manufacture optical fiber, polysilicon, silicon dioxide, etc., in communications, photovoltaic power generation, optical instruments and other fields of application; In addition, silicon tetrachloride can also be used in the military field, metallurgy, casting and other fields.

Contact Now

Distillation is the use of SiCl4, and the difference between the relative volatility of impurities components, through several partial gasification and partial condensation process, to achieve the separation of mixed liquid, so as to obtain high purity silicon tetrachloride products.

Contact Now

Silicon tetrachloride which chemical formula is SiCl4 is an inorganic compound, because silicon chloride only exists in the form of SiCl4, silicon tetrachloride is also directly called silicon chloride. The appearance of this product is light yellow liquid, and the appearance of high-purity silicon tetrachloride is colorless and transparent liquid, volatile, with special odor, toxicity and corrosion. Silicon tetrachloride can be miscible with benzene, chloroform, ether, carbon tetrachloride and other organic solvents. It can be hydrolyzed in humid air and react violently with water.

Contact Now

The main by-product of trichlorosilane, silicon tetrachloride, is also the main raw material for the manufacture of silicone, its finished products are silicone ester, silicone oil, high temperature insulating paint, silicone resin, silicone rubber and heat resistant cushion lining materials. High purity silicon tetrachloride is also an important raw material for manufacturing high purity silicon dioxide, inorganic silicon compounds, quartz fibers and optical fibers.

Contact Now

Silicon tetrachloride is mainly used in the manufacture of silicone esters, gaseous silica, silicone monomer, silicone oil, high temperature insulating paint, silicone resin, silicone rubber and so on. High-purity silicon tetrachloride is the main raw material for manufacturing fiber prefabricated rod, and the quality of fiber prefabricated rod directly determines the fiber performance. Therefore, high-purity silicon tetrachloride is the core raw material of fiber industry.

Contact Now

SiCl4 is one of the most important inorganic silicon compounds, is a colorless, transparent, flowing smoke liquid, with suffocating odor, soluble in benzene, ether, chloroform and other most organic solvents. Silicon tetrachloride is a volatile liquid with strong asphyxiating odor. It can be used as raw materials for the production of gaseous silica, high purity silicon and organosilicide. The upstream of the silicon tetrachloride industry chain is the raw material market, mainly silicon powder, ferrosilicon, hydrogen chloride, etc.

Contact Now

Chlorine hydrogenation technology is to add HCl on the basis of low temperature hydrogenation technology to further reduce the reaction temperature and increase the yield of trichlorosilane. Chlorine hydrogenation reaction principle is as follows: 2SiCl4(g)+H2(g)+HCl(g)+Si(s)=3SiHCl3(g). Hydrogen plasma is generated by hydrogen discharge, which is passed into the reactor to react with silicon tetrachloride gas. Since hydrogen is dissociated into hydrogen atoms, the reactivity is greatly increased and it can easily react with silicon tetrachloride to form trichlorosilane.

Contact Now

High temperature hydrogenation of silicon tetrachloride is an important method to treat silicon tetrachloride as a by-product of polysilicon. High temperature hydrogenation is silicon tetrachloride and hydrogen as raw materials, heated by 1200 ~ 1250℃ graphite heater, thermal reduction reaction to produce trichlorosilane. The advantages of the process are that the whole system is closed circulation, suitable for continuous and stable operation; Trichlorosilane products of high purity, need to distillation links less.

Contact Now

Silicon tetrachloride is an important raw material and intermediate product in the process of organic silicon synthesis and polysilicon production. Under different environmental conditions, silicon tetrachloride can react with a variety of substances to produce new substances.

Contact Now

At present, there are few reports on the quantitative analysis of dicyclohexylamine and impurities, so it is necessary to study them separately accurate quantitative analysis method. Since dicyclohexylamine has no ultraviolet absorption, the quantitative analysis method of dicyclohexylamine by high performance liquid chromatography evaporative light scattering detector was studied.

Contact Now

The process relates to a tail gas refining method, in particular to the hydrogenation of aniline to prepare cyclohexylamine and the deamination of dicyclohexylamine tail gas to refine hydrogen.

Contact Now

At present, there are two main synthesis methods of trichlorosilane: one is the traditional synthesis method, that is the silicon chloride method. The other is hydrolyzation of tetrachloride. At present, the mainstream method of polysilicon production is the modified Siemens method, using trichlorosilane reduction method. In recent years, with the continuous decline of polysilicon price, polysilicon production enterprises pay more and more attention to the control of production cost.

Contact Now

The principle is to reduce high purity trichlorosilane with high purity hydrogen on the high purity silicon core at about 1100℃ to generate polycrystalline silicon deposited on the silicon core. On the basis of the traditional Siemens process, the improved Siemens process is equipped with a supporting process of energy saving, consumption reduction, recycling and utilization of a large amount of H2, HCI, SiCI4 and other by-products and a large amount of by-production heat energy.

Contact Now

Colorless liquid with stinky smell. it will decompose with water and dissolve in carbon disulfide, carbon tetrachloride, chloroform, benzene, and many others. flammable, can spontaneously ignite inside the air. poisonous!SpecificationInChIKeyZDHXKXAHOVTTAH-UHFFFAOYAHUN number1295RTECSVV5950000Chemical FormulaSiHCl3Mole Mass135.4524 g·mol⁻¹Exteriorcolourless liquidDensity1.342 g/cm3Melting Point-126.6 °CBoiling Point31.8 °CSolubility (water)Decomposition by waterVapour Pressure0.660 bar (20 °C)It can undergo an addition reaction with olefins.

Contact Now

Colorless liquid with smelly odor. it'll decompose with water and dissolve in carbon disulfide, carbon tetrachloride, chloroform, benzene, and plenty of others. flammable, can spontaneously ignite within the air. toxic!It could go through an addition response with olefins.The hydrosilylation response of ethylene is as follows: cl3si-h + h2c=ch2 → cl3si-ch2-ch3 .

Contact Now

Colorless liquid with stinky scent. it's going to decompose with water and dissolve in carbon disulfide, carbon tetrachloride, chloroform, benzene, and lots of others. flammable, can spontaneously ignite in the air. poisonous!It may undergo an addition reaction with olefins.The hydrosilylation reaction of ethylene is as follows: cl3si-h + h2c=ch2 → cl3si-ch2-ch3 .

Contact Now

The production process of trichlorosilane is mostly prepared by reaction of gold-grade silicon metal powder and hydrogen chloride gas in a fluidized bed reactor. Generally using gold grade metal silicon powder, hydrogen chloride gas by the combustion reaction of chlorine and hydrogen gas. Reaction temperature is 300-400 degrees, most of the pressure using micro positive pressure operation.

Contact Now

Colorless liquid with pungent odor. It will decompose with water and dissolve in carbon disulfide, carbon tetrachloride, chloroform, benzene, etc. Flammable, can spontaneously ignite in the air. Poisonous! SpecificationInChIKeyZDHXKXAHOVTTAH-UHFFFAOYAHUN number1295RTECSVV5950000Chemical FormulaSiHCl3Mole Mass135.4524 g·mol⁻¹Exteriorcolourless liquidDensity1.342 g/cm3Melting Point-126.6 °CBoiling Point31.8 °CSolubility (water)Decomposition by waterVapour Pressure0.660 bar (20 °C)

Contact Now

Since May 2022, trichlorosilane has been sustained upward by the downward trend in silicon metal prices.

Contact Now

Trichlorosilane (TCS or SiHCl3) is generated as follows within a high temperature, pressurized reactor: Si + 3 HCl ➡ SiHCl3 + H2 ,Si + 3 SiCl4 +2 H2 ➡ 4 SiHCl3 .The TCS is then sent to the CVD (Chemical Vapor Desposition) reactor. In the Siemens process, high-purity silicon "starter" rods or hairpins are exposed to trichlorosilane at 1150 °C in the CVD reactor.

Contact Now

It is obtained by catalytic reduction of nickel or cobalt from aniline at high temperature and pressure. Cyclohexanol can also be reduced by phenol, oxidized to cyclohexanone, and then aminated with ammonia to obtain cyclohexanamine.This substance is harmful to the environment, and special attention should be paid to the pollution of water bodies. Acute poisoning may occur by inhalation of vapour. Irritant and corrosive to skin, eyes and mucous membranes, and can cause allergy through skin absorption.

Contact Now